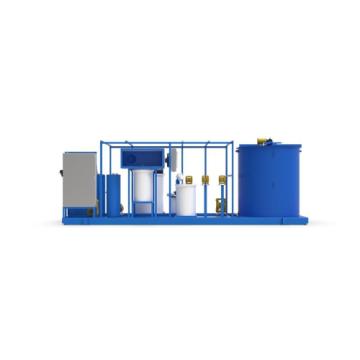

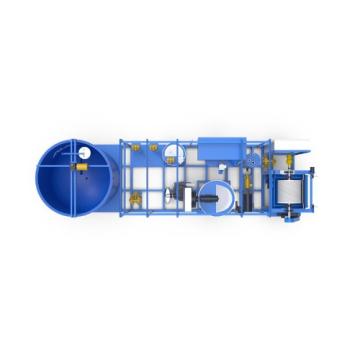

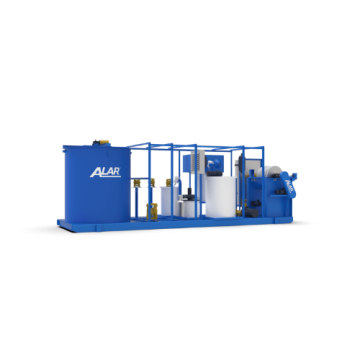

Flex-O-Star® Batch Dewatering System

The Flex-O-Star® is an automated skid-mounted, pre-piped and pre-wired industrial wastewater chemical batch pretreatment system with Auto-Vac® dewatering filter technology. ALAR's Flex-O-Star® liquid-solid separation system provides comprehensive industrial wastewater treatment for water-based effluents, slurries and problem wash waters.

The design is universal and works with virtually any industrial liquid waste.

The ALAR Flex-O-Star® incorporates a two-step liquid solid separation process:

Chemical (Pretreatment)

Mechanical (Dewatering Filtration)

STEP 1: Chemical Separation

The first step utilizes a chemical batch treatment tank with turbine mixer, along with various combinations of automatic pH, ORP and polymer (coagulant, flocculent) feed systems.

Chemical pretreatment increases the size and weight of the sub-micron particles in the wastewater. These particles are heavier than the liquid and fall “out of solution” in order to become filterable.

In most cases, the chemical separation step only requires pH adjustment in order to precipitate the solids. The Flex-O-Star® does not require a thick oatmeal-size floc or concentrated sludge settling. The solids only need to be bigger than one-micron (about half the size of a human red blood cell).

STEP 2: Mechanical Separation

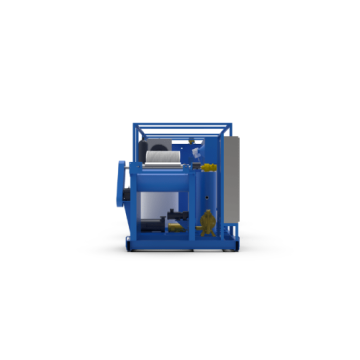

The second step utilizes the Auto-Vac® dewatering filter technology to physically remove the precipitated solid particles from the liquid.

The Auto-Vac® is a self-cleaning rotary vacuum drum precoat filter; capable of producing one-micron quality [non potable] water and dewatered, dry, [landfill-ready] solids.

Prior to filtering the pretreated wastewater, the Auto-Vac® drum surface is coated with a layer of porous filter aid media [Diatomaceous Earth (DE) or Perlite]. Once this “precoat cake” is built, the treated water pumps to a filter pan that the drum rotates in.

One-third of the drum is submerged in the pan, and two-thirds are exposed to ambient air. As the drum rotates in the pan, the water is vacuumed through the pre-coat media, and the solids accumulate on the cake surface. When the solids cover the filter media pores, a knife blade steps in with lathe-like precision; removing the solids and a small amount of filter aid. This self-cleaning process prevents blinding and clogging, while maintaining a clean filter surface.

The solids and filter quality are controlled through independent drum and knife speeds, along with filter pan level sensors.

ALAR designs and builds over sixteen Flex-O-Star® sizes. Contact ALAR to help find a custom-made industrial wastewater system solution.

The entire process of the Flex-O-Star® is automatic, which is built on a structural steel skid, pre-piped and pre-wired for easy installation.

Standard Flex-O-Star® Features Include:

System Support Skid

Structural carbon steel [welded and painted] skid that will support tank(s), mixer(s), pump(s), control cabinet, and Auto-Vac®

Skid-Mounted; Pre-Piped; Pre-Wired Components

Automatic PLC and Pneumatic Controlled

Automatic precoat filter cycle

Automatic wash-up cycle

Automatic chemical pretreatment cycle

Automatic filtration cycle

All controls programmed and mounted in Control Panel / PLC

NEMA 12 Control Panel

Automatic PLC Controls

Allen Bradley MicroLogix PLC

PanelView Touch Screen

pH / ORP Monitoring System

Treatment Tank

Carbon, Stainless or Fiberglass Dish Bottom Tank

Skid Mounted

Turbine Mixer and Support

Level Sensors

Controls Programmed into PLC

Automatic Chemical Feed System

Make-down tanks, metering pumps, or both

pH probe, ORP probe, or both

Automatic Sludge Transfer

PLC activated filter feed pump with regulator, ball valve and automatic solenoid control

Auto-Vac® Rotary Vacuum Drum Filter Technology

Contact ALAR to discover how the easy to operate Auto-Vac® can benefit your bottom line.

ALAR has sixteen (16) Flex-O-Star® sizes to choose from. Available in single or continuous batch systems. The solids loading, volume and amount of hours per day will factor into the equipment size.

Contact an ALAR representative to determine which Flex-O-Star® system is best suited for your industrial wastewater process.

Replacement Parts

The ALAR Engineering Department designs each system to meet the customer's build-to specifications. ALAR begins with stock layouts, and customizes the auxiliary equipment according to the customer's specifications.

These stock layouts are available in PDF format. Contact ALAR for more information.